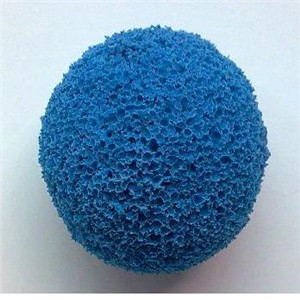

EPDM Rubber

EPDM Rubber compound is made of vinyl raw rubber, silica, bridge-erecting agent, structural control agent, coupling agent and other materials through high temperature mixer. Ethylene propylene diene monomer (EPDM) is the blank of rubber products, that is, semi-finished products. Therefore, the colloidal dispersion quality of EPDM is directly related to the quality of finished products. At the same time, the viscoelasticity and rheological properties of EPDM directly affect the processing technology of calendering and extruding.

EPDM Rubber Compound (EPDM) is mainly used in industrial miscellaneous parts (seals, oil seals, O-gaskets, rollers, insulating pipes). Characteristic and technical index of low temperature organosilicon rubber mixtures Rapid curing at low temperature (120 C) without secondary baking and environmental protection - no odor, no harmful gas, good yellowing resistance, and stable product size.

- In the previous:CPE Rubber

- The next article:FKM Rubber