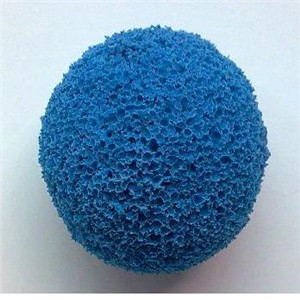

HNBR Rubber

Hydrogenated nitrile-butadiene rubber (HNBR) is a highly saturated elastomer obtained by special hydrogenation of nitrile-butadiene rubber. Hydrogenated nitrile-butadiene rubber has good oil resistance (good resistance to fuel oil, lubricating oil and aromatic solvents); and because of its highly saturated structure, it has good heat resistance, excellent chemical corrosion resistance (good resistance to freon, acid and alkali), excellent ozone resistance, high compression permanent deformation resistance; Nitrile butadiene rubber (NBR) is one of the excellent rubber with high strength, tear resistance and wear resistance.

HNBR has high temperature resistance of 130 - 180 C, cold resistance of - 55 - 38 C and excellent mechanical properties. Compared with other polymers, HNBR can better meet the requirements of automobile industry. HNBR reinforced by zinc oxide/methacrylic acid (MAA) can be used to make triangular belt, isotactic triangular belt, bottom glue of multi-purpose triangular ring, vibration isolator, sealing ring, sealing parts, heat-resistant pipe, etc. In oil drilling, rubber products are required to withstand high temperature, high pressure, acid, amine, H2S, CO2, CH4 and other steam tests. The products prepared by HNBR can resist acid, oil and solvent. HNBR reinforced by ZnO/MAA can be used to make pistons for drilling protection box and mud pump. In addition, paper gaskets made of HNBR by beating method can be used as sealing gaskets in petroleum industry and automobile industry. The heat and radiation resistance of HNBR is better than that of silicone rubber, fluorine rubber and polytetrachloroethylene. It is suitable for various rubber seals in power stations, as well as for hydraulic pipes, hydraulic seals, cable sheaths for power stations, printing and fabrics rollers, weapon components and aerospace seals, covers, fuel bags, etc. The HNBR latex can be used as surface coatings (paintings), textiles, paper, leather, metals, etc. Adhesives for ceramics and non-woven fabrics, foamed rubber and impregnated latex products, etc. In addition, the comprehensive performance of HNBR reinforced by ZnO/MAA, peroxide and high wear resistance furnace is better than that of ordinary HNBR.

Application:

Hydrogenated nitrile-butadiene rubber (HNBR) is widely used in oil field and automobile industry. Ruiweng Company is the main supplier of hydrogenated nitrile rubber raw materials, and has rich experience in formulation and processing of hydrogenated nitrile rubber. According to the different application fields, we can specialize in providing mixed rubber products with complete varieties, excellent performance and stable quality, as well as various hydrogenated nitrile butadiene rubber sheets and moulded products.

With the development of automotive and petroleum industry, rubber parts not only require oil resistance, but also have good heat resistance, high temperature resistance, high pressure, oxygen resistance and other characteristics. Normal nitrile-butadiene rubber (NBR) is far from meeting these requirements. Although some of its uses have been replaced by fluororubber, fluororubber is expensive. Therefore, people began to explore the improvement of NBR performance. Hydrogenated nitrile butadiene rubber was successfully developed to meet this new need.

- In the previous:FKM Rubber

- The next article:NBR Rubber