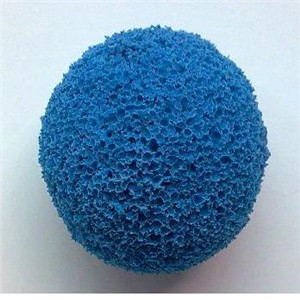

NBR Rubber

NBR Rubber Compound is made from butadiene and acrylonitrile by emulsion polymerization. NBR rubber is mainly produced by low temperature emulsion polymerization. It has excellent oil resistance, high wear resistance, good heat resistance and strong adhesion. Its shortcomings are poor low temperature resistance, poor ozone resistance, poor electrical performance and slightly low elasticity. NBR is mainly used in the manufacture of oil-resistant rubber products.

Performance characteristics:

NBR Rubber is made from butadiene and acrylonitrile by emulsion polymerization. NBR rubber is mainly produced by low temperature emulsion polymerization. It has excellent oil resistance, high wear resistance, good heat resistance and strong adhesion. Its shortcomings are poor low temperature resistance, poor ozone resistance, poor electrical performance and slightly low elasticity. NBR is mainly used in the manufacture of oil-resistant rubber products.

Main uses:

NBR rubber is mainly used to produce oil-resistant products, such as tubing, tape, rubber diaphragm and large oil bag. NBR rubber is often used to produce various kinds of oil-resistant die pressing products, such as O-rings, oil seals, leather bowls, diaphragms, valves, bellows, etc. It is also used to make rubber sheets and wear-resistant parts.

NBR blend is based on NBR rubber, with vulcanizing agent, accelerator and other chemicals, NBR rubber can be directly used in the production of moulded products.

- In the previous:HNBR Rubber

- The next article:NR Rubber